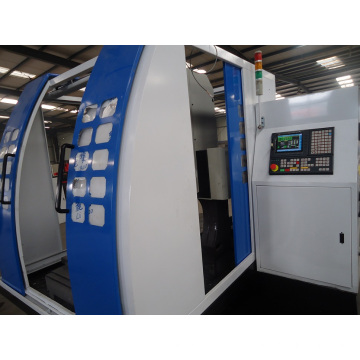

Mould Milling Machine 3D Mold Metal Engraving Machine

Basic Info

Model No.: TZJD-6060MBN

Product Description

Model NO.: TZJD-6060MBN Controlling Mode: CNC Milling Cutter Diameter: 10mm Certification: ISO9001, CE, SGS FDA Customized: Customized Working Area: 600mm*600mm*300mm Structure: Germany Ballscrew Working Table: Bakelite Table Combined Aluminum T-Slot Extrusion Control System: Syntec Lnc Ncstudio Guide: Taiwan Hiwin Square Linear Bearings Trademark: TZJD Specification: CE FDA SGS ISO BV HS Code: 84609090 Carving Material: Carbon Steel Main Axle Rotational Speed: ≤24000rpm Feeding Height: >300mm Warranty: 24 Months Condition: New Spindle: 5.5kw Permenent Torque Spindle Power Machine Color: Blue Black Motor Driver: Japan Panasonic Servo Cooling System: Spray Mist Cooling System Software: Type3 Artcam Ucancam Transport Package: Fumigating Wooden Packaging Origin: Shandong China Mould Milling machine 3D Mold Metal Engraving machine TZJD-6060MBN

1. Specification Parameter:

2. Applicable materials:

Iron, stainless steel, copper, aluminum, plastic, marble, aluminum plate, timber, KT board, ABS board,

PVC board, acrylic, jade, sign board, mould, bronzing, badge, pattern mould, art carve, coin dyes, etc.

3. Product features:

1) Integrally cast lathe bed, firm and non-deforming, high rigidity and high accuracy, adopts Taiwan HIWIN line guide rail.

2) The gantry was confirmed and the working table can be move manipulable, improve the working-efficiency.

3) Tool sensor system, save extra time to adjust the machine.

4) Use high speed Japan Panasonic Servo motor driver, largely improve the working-efficiency.

5) Memory function ensures the processing point when the blade is broken or having to postpone the process.

6)With better compatibility, can math with many programs such as Typle3, artcam, castmate, proE, Coreldraw/CAD,CAM. It achieves 2D and 3D works easily.

7) This type machine can support these functions: drilling/milling, engraving/carving, cutting.

8) It widely used for small materials working, without noise & high-power. Many gear speed regulation and control function & Curve and linear speed independent control.

9) Water tank system on the body & water-cooled system automatically.

10) Taiwan LNC control system. Use this control system, it can prolong the machine's working-life.

4. Packages: Solid seaworthy wood box package with steel belt.

5. Guarantee and After-sales service:

1) The quality warranty period is 24 months which counted from the day that the shipping commodity arrived at the port of destination, excluding the physical damage, We will provide you with the fittings for free during the guarantee period. But please kindly note that all users are kindly required to return us the damaged fittings by courier with your charge before we send back the alternative fitting parts. After warranty period, the fittings which you need repaired or changed should be in charge by you, and it will be reasonable charged.

2) Since it is difficult for our engineer to maintain the machine by face to face, we will create a plenty of online-supports. That is to say, we will give you technical supports by email, MSN/Skype, camera, video, telephone and fax when user meets some problems on installing, operating, adjusting, maintaining, and so on.

3) When you meet some problems with installing, using or adjusting, but our online-support can not solve it, we can offer Door to Door service. If you need our engineer(s) to assemble or maintain or adjust the machine in your area, you would like to be required to assist us to go through the visa formality, traveling expenses prepaid and accommodation arrangement during the business trip and the service period before they dispatched. And please kindly arrange the translating person for the service engineer during their service period. Otherwise, you also can arrange your engineer to come to visit our factory to get a long-term free technical training.

6. Traning to use:

1) We will supply you with the operation and installation manual in English version together with the machine, including introduction for the composing of equipment, working principle, common knowledge of computer, controlling principle of electronic devices, daily maintenance measures. Personal demonstration will be supplied for equipment installing, adjusting, operating, programming of computer and common malfunction eliminating measures, etc.

2) We will supply you with brochures for simple trouble shootings of the machine which can help you deal with the common problems happened unexpectedly. Meanwhile, one set of "Instruction Book", "Operation Manual" and "Training Video Disk" for machine / software will be also sent to you together with the machine that could be easily understood and kindly handled by you and your customer.

7. Company information:

Tengzhou Jianda CNC Machine Co., Ltd specialized in woodworking machine,advertising machine, marble/stone engraving machine, laser engraving cutting machine, metal mould machine, double heads engraving machine,cylinder engraving machine, etc. The company was one of companies that can research & develop the advanced CNC Machines, which have laid the foundation in the domestic market. our machines have already exported to USA, Canada, England, Australia, Russia, India and so on.

8. FAQ:

1) How long is the delivery time?

For standard machines, it would be 5-8 days; For non-standard machines and customized machines according to client s specific requirements, it would be 8 to 15 days.

2) How about the payment terms?

T/T, West Union, L/C

3) Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

4) If some problems happened to this machine during warranty period, what should I do?

We will supply free parts in machine warranty period if machine have some problem. While we also supply free after-service forever, so any doubts, just let us know, we will give you solutions in 24 hours.

5) What is the MOQ?

MOQ for our products is 1 set machine, we could send it to your country port if you tell detail information about your country port.

9. Contact information:

Mobile: +86-18615627569

Contact us if you need more details on Mould Milling Machine 3D Mold Metal Engraving. We are ready to answer your questions on packaging, logistics, certification or any other aspects about CNC Router、Metal Engraving Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Specification Parameter:

| Description | Parameter |

| TZJD-6060MBN | |

| Working Area (X*Y*Zmm) Plat form size(X*Y) | 600mm*600mm*300mm 640mm*640mm |

| Max Engraving Speed Max Running speed | 6000mm/min 12000mm/min |

| Frame | Cast Steel |

| Spindle power(KW) | 5.5kw permenent torque spindle |

| Max. Power Consumption(Without spindle) | 3KW |

| Spindle Speed | 24000rpm |

| Resolution | 0.005mm |

| Repeatability | 0.01mm |

| Voltage | AC220V,50Hz/60Hz(option:AC110V,50Hz/60HZ) |

| Drive motor | Japan Panasonic Servo motor |

| Working Dictate | G Code*.u00*.mmg*.plt |

| Operating system | Taiwan LNC control system |

| Software environment | Windows98/2000/xp/7 |

| Interface | USB |

| Flash memory | 128M(U Disk) |

| Software Compatability | Type3,,Ucancam,Artcam Software) |

| Diamerer of cutter Table Max load Dimension(L*W*H) Weight | 3.175mm, 6mm, 12.7mm, 2,1, etc. 300kg 1.8m*1.35m*2.1m 2800kg |

| Running Environemt | Temperature: 0ºC~45ºC |

| Relative humidity: 30%~75% | |

| Machine necessary | Cast heavy-thickness steel structure, High precision HIWIN Square linear bearings, Dust cover system, control system integration shell, spindle cover, Japan Panasonic Servo motor, Auto-oiling system, Tool-sensor, water tank system, water-cooled system. |

2. Applicable materials:

Iron, stainless steel, copper, aluminum, plastic, marble, aluminum plate, timber, KT board, ABS board,

PVC board, acrylic, jade, sign board, mould, bronzing, badge, pattern mould, art carve, coin dyes, etc.

3. Product features:

1) Integrally cast lathe bed, firm and non-deforming, high rigidity and high accuracy, adopts Taiwan HIWIN line guide rail.

2) The gantry was confirmed and the working table can be move manipulable, improve the working-efficiency.

3) Tool sensor system, save extra time to adjust the machine.

4) Use high speed Japan Panasonic Servo motor driver, largely improve the working-efficiency.

5) Memory function ensures the processing point when the blade is broken or having to postpone the process.

6)With better compatibility, can math with many programs such as Typle3, artcam, castmate, proE, Coreldraw/CAD,CAM. It achieves 2D and 3D works easily.

7) This type machine can support these functions: drilling/milling, engraving/carving, cutting.

8) It widely used for small materials working, without noise & high-power. Many gear speed regulation and control function & Curve and linear speed independent control.

9) Water tank system on the body & water-cooled system automatically.

10) Taiwan LNC control system. Use this control system, it can prolong the machine's working-life.

4. Packages: Solid seaworthy wood box package with steel belt.

5. Guarantee and After-sales service:

1) The quality warranty period is 24 months which counted from the day that the shipping commodity arrived at the port of destination, excluding the physical damage, We will provide you with the fittings for free during the guarantee period. But please kindly note that all users are kindly required to return us the damaged fittings by courier with your charge before we send back the alternative fitting parts. After warranty period, the fittings which you need repaired or changed should be in charge by you, and it will be reasonable charged.

2) Since it is difficult for our engineer to maintain the machine by face to face, we will create a plenty of online-supports. That is to say, we will give you technical supports by email, MSN/Skype, camera, video, telephone and fax when user meets some problems on installing, operating, adjusting, maintaining, and so on.

3) When you meet some problems with installing, using or adjusting, but our online-support can not solve it, we can offer Door to Door service. If you need our engineer(s) to assemble or maintain or adjust the machine in your area, you would like to be required to assist us to go through the visa formality, traveling expenses prepaid and accommodation arrangement during the business trip and the service period before they dispatched. And please kindly arrange the translating person for the service engineer during their service period. Otherwise, you also can arrange your engineer to come to visit our factory to get a long-term free technical training.

6. Traning to use:

1) We will supply you with the operation and installation manual in English version together with the machine, including introduction for the composing of equipment, working principle, common knowledge of computer, controlling principle of electronic devices, daily maintenance measures. Personal demonstration will be supplied for equipment installing, adjusting, operating, programming of computer and common malfunction eliminating measures, etc.

2) We will supply you with brochures for simple trouble shootings of the machine which can help you deal with the common problems happened unexpectedly. Meanwhile, one set of "Instruction Book", "Operation Manual" and "Training Video Disk" for machine / software will be also sent to you together with the machine that could be easily understood and kindly handled by you and your customer.

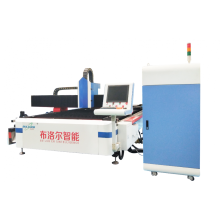

7. Company information:

Tengzhou Jianda CNC Machine Co., Ltd specialized in woodworking machine,advertising machine, marble/stone engraving machine, laser engraving cutting machine, metal mould machine, double heads engraving machine,cylinder engraving machine, etc. The company was one of companies that can research & develop the advanced CNC Machines, which have laid the foundation in the domestic market. our machines have already exported to USA, Canada, England, Australia, Russia, India and so on.

8. FAQ:

1) How long is the delivery time?

For standard machines, it would be 5-8 days; For non-standard machines and customized machines according to client s specific requirements, it would be 8 to 15 days.

2) How about the payment terms?

T/T, West Union, L/C

3) Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

4) If some problems happened to this machine during warranty period, what should I do?

We will supply free parts in machine warranty period if machine have some problem. While we also supply free after-service forever, so any doubts, just let us know, we will give you solutions in 24 hours.

5) What is the MOQ?

MOQ for our products is 1 set machine, we could send it to your country port if you tell detail information about your country port.

9. Contact information:

Mobile: +86-18615627569

Contact us if you need more details on Mould Milling Machine 3D Mold Metal Engraving. We are ready to answer your questions on packaging, logistics, certification or any other aspects about CNC Router、Metal Engraving Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : CNC Router

Premium Related Products

Other Products

Hot Products

Automatic Preformer (SJ250B)Economical CNC Wire Cutting Machine (Series SJ/DK7732)EDM SPARKING HG-40wire cut edm machine low price FH-300C0.18mm molybdenum wire for edm machineHL control system card for wire edm machinecnc gantry milling machinesdie sinking edm machinespark erosion machineFZC7750 Series Middle Speed EDM Cutting Machineengraving machine for salemachine center for salecnc milling machine for salefull-enclosed edm wire cut machineedm drilling machinewire cut machine for sale