HL control system card for wire edm machine

Basic Info

Model No.: HL-V700E

Product Description

HL Control System Card for wire edm machine !!! HL control system card for wire edm machine -Features: HL system is currently one of the most popular wire cutting control systems available. lts powerful features, high reliability and high stability have been widely recognized throughout the industry. The HL-PCI version changes the original HL ~ ISA interface to the more advanced PCI interface. As PCI interface of advanced features makes the bus of HL-PCI card and machine control part better separate, HL system is further enhanced on anti-interference capability and stability. Furthermore, the wire installation is less complicated and maintenance is simplified. The HL-PCI card requires less computer configuration and better compatibility than ISA card. It can be started without a hard disk or a floppy disk. Main Features l. A multi-control function, that one computer can controls as many as four machines to cut different work-pieces at the same time, and programming while processing. 2. Taper processing adopts a 4 0r 5-axis link-move control technology. The two taper machining methods of top-bottom different shapes and simply angle-input, make taper processing become faster and easier. It can also process changed-taper and equal arc. 3. Simulate machining, fast show machining track, particularly the track of that taper and top-bottom sides of top-bottom different shape work-piece, and display the coordinates of final point. 4. Real-time display graphics machining process, by switching the screen, monitoring the machining status of four machines at the same time, and shows the relative coordinates of X, Y, J and absolute coordinates of X, Y, U, V, and other changed value. 5. Power off protection, that sudden power off during machining, after power on, each machine automatically returns to machining status. The storage documents in system can be long-term retained. 6. Accurate adjust calculation to the base-plane and wire frame distance. Offset in U and V direction to the offset by the guided pulley cutting point, to enhance the accuracy of taper machining, the accuracy of big taper cutting is significantly better than similar software. 7. Scan gallery to quickly find the necessary documents. 8. Mo wire offset (not necessarily increase the transition circle), the machining scale adjustments, coordinate transformation, the recycle machining, the stepper motor speed, automatic short-circuit regression, and other features. 9. Can start machining from any segment, and stop at any segment. Can forward l reverse machining. 10. Can set (or cancel) at any time pause after machining present segment instructions. 11 .Pause, stop and short-circuit automatically rolled back and short-circuit long time (one minute) alarm. 12. Data conversion between AUTOCAD DXF format and ISOG format. 13. Access to customer network systems, exchange of data and monitor each machining process in network system (option). 14. Machining interpolated radius up to 1,000 meters. 15. Machining automatically accumulate working hours, easy for production management. 16. Machine installed with optical scale, can realize closed-loop control. 17. Multi-time cutting function designed for middle wire-speed machine.

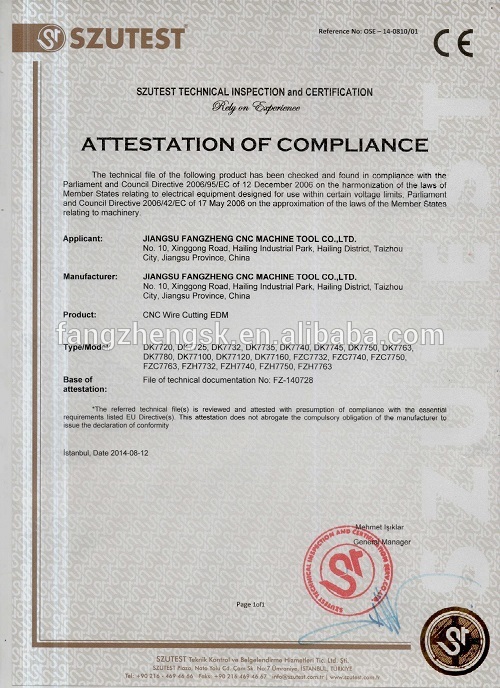

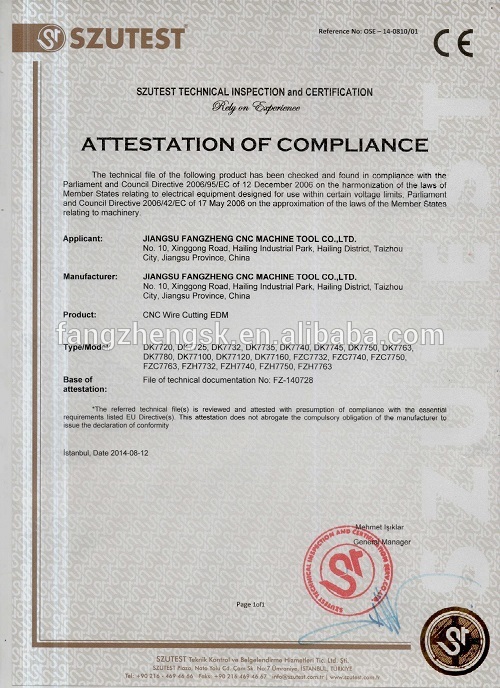

Contact us if you need more details on Hl Control System Card. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Hl Card for Wire Cut Machine、Hl Control System Card. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Hl Control System Card. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Hl Card for Wire Cut Machine、Hl Control System Card. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Hl Control System Card. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Hl Card for Wire Cut Machine、Hl Control System Card. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Hl Control System Card. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Hl Card for Wire Cut Machine、Hl Control System Card. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Control System Card

Premium Related Products

Other Products

Hot Products

Automatic Preformer (SJ250B)Economical CNC Wire Cutting Machine (Series SJ/DK7732)EDM SPARKING HG-40wire cut edm machine low price FH-300C0.18mm molybdenum wire for edm machineHL control system card for wire edm machinecnc gantry milling machinesdie sinking edm machinespark erosion machineFZC7750 Series Middle Speed EDM Cutting Machineengraving machine for salemachine center for salecnc milling machine for salefull-enclosed edm wire cut machineedm drilling machinewire cut machine for sale