mini wire edm machine FH-300C model

Basic Info

Model No.: FH-300C mini wire edm machine

Product Description

FH-300C mini wire edm machine

Automactic Generation for Parameter: Only need to put in: Thickness, Molywire Diameter, etc, Machine Will Work Out the PERFECT parameter by itself. Machine Accuracy : ±0.004mm Automatic

Normal Brand: 0.012-0.015mm

Max Machining Speed: 200mm2/min

Normal Brand: 70-150mm2/min

Roughness: Ra ≤0.8um

Normal Brand: Ra ≤1.2um-1.5um

Thickness for 3 Time Cutting: ≥200mm

Normal Brand: ≥100mm

Main Accessorys ( Standard Accessory )

Adopts a word famous PANASONIC Transducer control system, which can make the direction changing more smoothly .be used longer time, improve the precision, roughness and reduce the wire broken.

All of the machine is equipped with precious ball screw and linear guideway, which purchased top quality one from Hiwin in Taiwan.

Newest waterproof copper pulley, make long life working for the bears. Double pump filter control system, match more filter accessories (more tiers filtering) to clean the working solution, so the working solution can be used for longer time.

Machine equip with high precision DRO (optional accessory), achieve 3 axis reading out.

Industrial Computer Adopt Industrial Computer to make sure the System working stably.

Retrofitting folding water flushing system to protect the working solution, avoid the working solution splash out. The basic framework of the controller adopt professional profiles and connection fixed facilities by the technology from German, the controller has realized both elegant appearance outside and rational layout inside. The effect of sealing, electromagnetic compatibility and heat dissipation is well and the controller must be high temperature aged before being sold to make sure the components be able to work for a long time continuously.

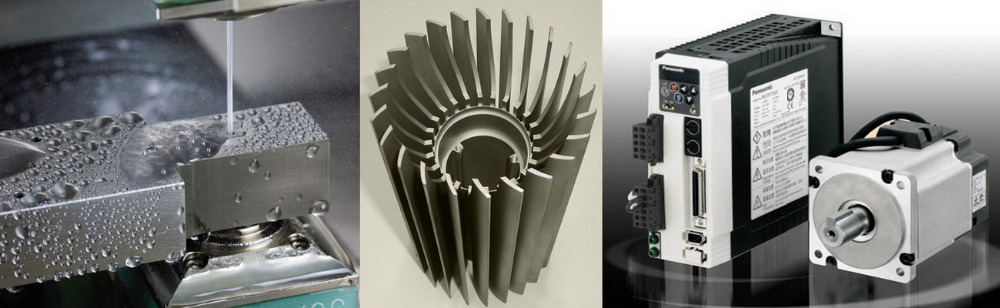

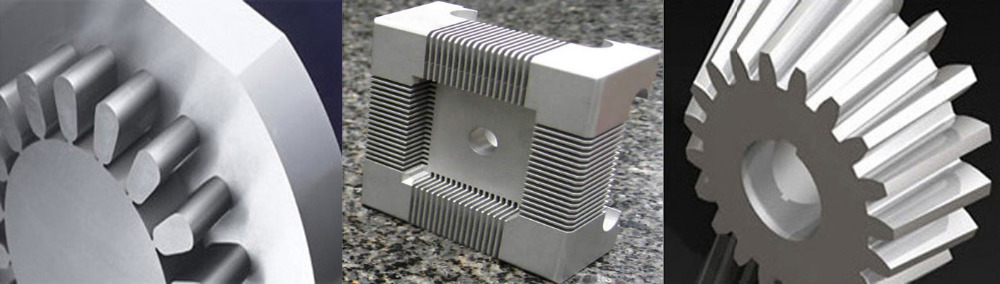

Only need to put in cutting thickness, your request and moly-wire diameter, the system will work out the parameter by itself, no need to set parameter by yourself, just like automatic transmission car, which is easier than manual transmission car. Other Cutting Samples

Machine equip with higher efficiency and lower consume controller, which can make the thickness for 3 times cutting≥200mm, highly improve the surface smooth of the work-piece, and reduce more than 50% consume of the molybdenum wire.

Max. Current 6A, max efficiency>=200m2/min, surface roughness<=0.8um. The modular design is used in the internal wiring, which can reduce the probability of the failure, and it’s easy to maintain.

Factory Pictures:

Factory Pictures:

Contact us if you need more details on Mini Wire Edm Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mini Wire Edm Machine Low Price、Mini Wire Edm Machine High Quality. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Mini Wire Edm Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mini Wire Edm Machine Low Price、Mini Wire Edm Machine High Quality. If these products fail to match your need, please contact us and we would like to provide relevant information.

Automactic Generation for Parameter: Only need to put in: Thickness, Molywire Diameter, etc, Machine Will Work Out the PERFECT parameter by itself. Machine Accuracy : ±0.004mm Automatic

Normal Brand: 0.012-0.015mm

Max Machining Speed: 200mm2/min

Normal Brand: 70-150mm2/min

Roughness: Ra ≤0.8um

Normal Brand: Ra ≤1.2um-1.5um

Thickness for 3 Time Cutting: ≥200mm

Normal Brand: ≥100mm

| Item | unit | FH-300C mini wire edm machine |

| Worktable size (L×W) | mm | 460*600 |

| Table travel(X×Y) | mm | 300*350 |

| Max. work piece thickness | mm | 250 |

| U.V axis | mm | 15*15 |

| Max. taper angle/plate thickness | degree/mm | ±3°/80 |

| Wire diameter | mm | 0.10-0.18 |

| Precision(3time cutting,Gr12,S=40) | mm | ±0.004 |

| Roughness, thrice cutting | um | ≤0.8 |

| Max. machining speed | mm²/min | 200 |

| Machine dimensions(W×L×H) | mm | 1100*1650*1750 |

| Machine weight | Kg | 1800 |

| Controller dimensions(W×L×H) | Mm | 600*600*1800 |

| Wire traveling speed | m/min | 5-11 |

| Load of table | Kg | 400 |

| Rated Power | KVA | 3 |

| Water tank dimension(W×L×H) | mm | 600*1200*500 |

| Working reservoir capacity | L | 200 |

Adopts a word famous PANASONIC Transducer control system, which can make the direction changing more smoothly .be used longer time, improve the precision, roughness and reduce the wire broken.

All of the machine is equipped with precious ball screw and linear guideway, which purchased top quality one from Hiwin in Taiwan.

| Hiwin Ball Screw Linear Guide Way |

|---|

|

Newest waterproof copper pulley, make long life working for the bears. Double pump filter control system, match more filter accessories (more tiers filtering) to clean the working solution, so the working solution can be used for longer time.

Machine equip with high precision DRO (optional accessory), achieve 3 axis reading out.

Industrial Computer Adopt Industrial Computer to make sure the System working stably.

Retrofitting folding water flushing system to protect the working solution, avoid the working solution splash out. The basic framework of the controller adopt professional profiles and connection fixed facilities by the technology from German, the controller has realized both elegant appearance outside and rational layout inside. The effect of sealing, electromagnetic compatibility and heat dissipation is well and the controller must be high temperature aged before being sold to make sure the components be able to work for a long time continuously.

Only need to put in cutting thickness, your request and moly-wire diameter, the system will work out the parameter by itself, no need to set parameter by yourself, just like automatic transmission car, which is easier than manual transmission car. Other Cutting Samples

|

| Vertical Cutting |

|---|

|

|

Max. Current 6A, max efficiency>=200m2/min, surface roughness<=0.8um. The modular design is used in the internal wiring, which can reduce the probability of the failure, and it’s easy to maintain.

| Vertical Cutting Tape Cutting |

|---|

|

Factory Pictures:

Factory Pictures:

Contact us if you need more details on Mini Wire Edm Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mini Wire Edm Machine Low Price、Mini Wire Edm Machine High Quality. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Mini Wire Edm Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mini Wire Edm Machine Low Price、Mini Wire Edm Machine High Quality. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : EDM Wire Cutting Machine

Premium Related Products

Other Products

Hot Products

Automatic Preformer (SJ250B)Economical CNC Wire Cutting Machine (Series SJ/DK7732)EDM SPARKING HG-40wire cut edm machine low price FH-300C0.18mm molybdenum wire for edm machineHL control system card for wire edm machinecnc gantry milling machinesdie sinking edm machinespark erosion machineFZC7750 Series Middle Speed EDM Cutting Machineengraving machine for salemachine center for salecnc milling machine for salefull-enclosed edm wire cut machineedm drilling machinewire cut machine for sale